Key Points

- Cyber security is often the driving force behind IT/OT asset management because you can’t protect what you can’t see. However, cybersecurity is not always a priority for engineers.

- OT asset management is integral to OT engineering as it ensures assets are maintained and used efficiently.

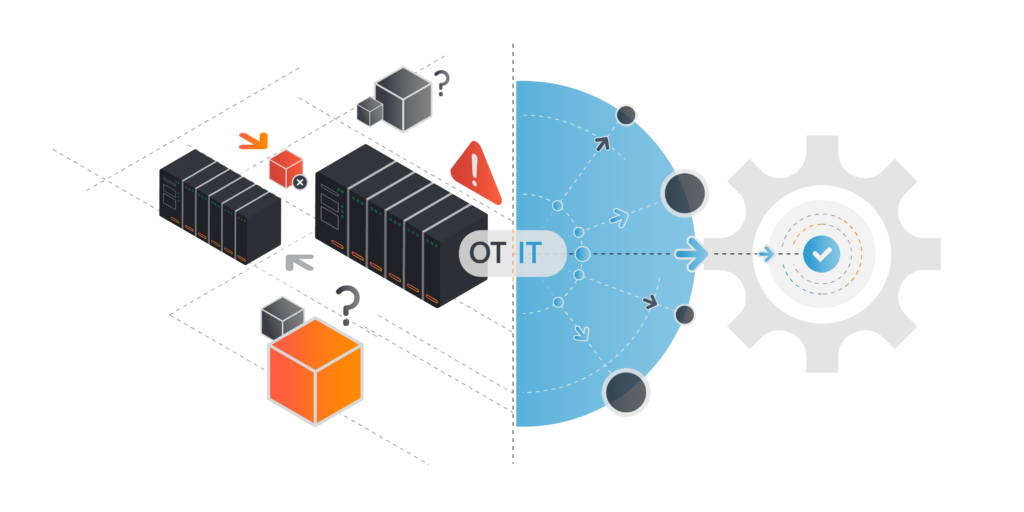

- A unified approach to OT/IT asset management provides data about OT assets, IT assets, and infrastructure that helps engineering, maintenance, plant admin, and IT/OT cyber security teams complete tasks faster.

- Lansweeper for OT solves the challenges of OT discovery, enabling organizations to combine OT and IT data for complete visibility and control.

Is Cyber Security a Priority for Engineers?

ICS/OT engineers design, implement, and maintain industrial control systems across various sectors, ensuring these systems operate efficiently to meet organizational needs. They handle a range of hardware and software from various OEMs and vendors, taking charge of everything from system design to installation and configuration of components like sensors and network devices. Their work includes rigorous testing and troubleshooting issues ranging from connectivity problems to hardware failures.

Automation engineers focus on designing and maintaining systems that automate processes to enhance efficiency across industries such as manufacturing, mining, and energy production. Their goal is to minimize human intervention by automating repetitive tasks, ensuring smooth operations.

In both roles, the primary goal is to ensure the safety, reliability, and productivity of operational systems. However, cybersecurity often takes a backseat in industrial automation settings.

Why Engineers Should Care about OT Asset Management

Asset management is an integral part of OT (operational technology) engineering as it ensures that assets are kept in good condition and utilized efficiently, maximizing their potential.

OT Asset Management allows engineers to:

- Improved Efficiency and Reliability: OT asset management provides a comprehensive view of the asset’s condition and performance, enabling proactive maintenance and minimizing downtime. This leads to improved system reliability – a critical benefit since equipment failures can severely disrupt operations.

- Cost Savings: By maintaining an accurate inventory of all operational assets and their conditions, engineers can optimize the use of resources and reduce costs. They can eliminate redundant assets, improve maintenance scheduling to prevent costly emergency repairs and extend equipment life cycles.

- Compliance and Reporting: OT asset management systems help ensure compliance with stringent safety and maintenance regulations by providing tools for accurate record-keeping and reporting.

- Strategic Decision Making: With detailed insights from OT asset management tools, engineers can make informed decisions regarding equipment upgrades and investments, boosting operational efficiency and competitive advantage.

To sum it up, effective OT asset management is important to engineers because it helps to enhance operational security, efficiency, and compliance while reducing costs and supporting strategic operational decisions.

Watch this demo video to learn how to set up Lansweeper for OT.

WATCH NOWWhy Not Just Extend IT Asset Management?

Asset management has been part of IT professionals’ jobs for many years, so why can’t we use the same tools and platforms in the OT environment?

As we covered in our previous entry, ‘Why is OT inventory more complicated than IT inventory,’ network scanning techniques designed for IT are known to be problematic in OT/ICS.

First of all, OT Assets can be rather sensitive. OT network scanning in operational or production environments can cause malfunctions or physical damage to machinery. OT/ICS systems are designed for real-time operations, amplifying the risks of unintended consequences.

Secondly, the protocols are different. IT protocols like SNMP can’t be used to detect most OT assets. To discover these devices, industrial protocols such as Ethernet/IP, Profinet, Modbus, SERCOS, and ControlNet must be used. Unfortunately, these protocols are not often present in a “typical” IT asset management system.

Finally, in comparison to IT, OT networks have more complex and less homogeneous architectures. It’s possible for OT assets to be connected to multiple networks at the same time – further complicating the asset discovery based on IP alone.

Given all these factors, combining OT and IT asset management is a must for organizations looking to protect and optimize their entire technology estate.

Where OT Asset Management Meets IT and Cybersecurity

Cyber security is often the driving force behind IT/OT asset management as it is essential to identify the assets before one can protect them. Accurately determining the network topology, installed hardware, and software product versions is essential for making an effective effort to strengthen the cyber security posture.

A unified approach to OT/IT asset management yields valuable data about OT and IT assets and infrastructure that helps engineers, maintenance specialists, plant administrators, and IT/OT cybersecurity teams work together to protect the OT/IT estate and complete tasks much faster than before.

However, this requires a unified approach:

- Clearly defined roles and responsibilities. Establish who is doing what in terms of OT/IT asset management, including who is responsible for asset tracking, maintenance, and disposal.

- Provide cross-functional training programs. Training can be provided to align team members around the asset management processes and tools. In this way, OT and IT teams can work together more effectively to ensure that all assets are properly managed throughout their lifecycle.

- Maintain a single source of truth for data from all connected assets. While each team will interpret the data differently, a consolidated view helps to align OT and IT teams around asset management, enabling clear communication and collaboration.

All Your IT, IoT and OT – In One Place

The Lansweeper solution is designed for IT/OT asset management. It provides a centralized platform for discovering, tracking, and managing IT and OT assets across an organization.

Lansweeper OT utilizes custom-made discovery capabilities to accurately detect and recognize any OT devices and systems, including PLCs, flow meters, card scanners, security cameras, and other equipment that is traditionally managed separately from IT assets.

It collects and delivers detailed information about each device, including the manufacturer, model, serial number, firmware versions, and more.

With Lansweeper, engineers and cybersecurity teams are empowered to:

- Plan and manage changes, maintenance, and equipment refreshes

- Enable the remediation of firmware vulnerabilities

- View detailed, complete inventory information for all OT assets

Lansweeper has advanced its scanning technology to develop a new solution tailored for identifying industrial OT devices from top manufacturers like Siemens and Rockwell Automation. This enhancement is part of Lansweeper OT, a robust software designed to unify the management of IT and OT assets, facilitating closer collaboration between engineering, IT, and cybersecurity teams.

With Lansweeper OT, organizations can generate a detailed inventory of their OT assets, integrating this information into Lansweeper’s extensive datastore that also includes IT and IoT assets. This integration offers a unified view of all assets through a single interface, supporting IT teams in making informed decisions to optimize and secure their entire technology infrastructure.

OT and IT: Better Together

Lansweeper understands that the real value to an industrial organization lies in the ability to bring different teams together around a unified picture of the company’s assets – whether they be IT or OT. This paves the way for collaboration between different parts of the organization and is the only way to ultimately minimize the overall cyber risk to the company.

Learn more about Lansweeper for OT, or start a free trial today.